![]()

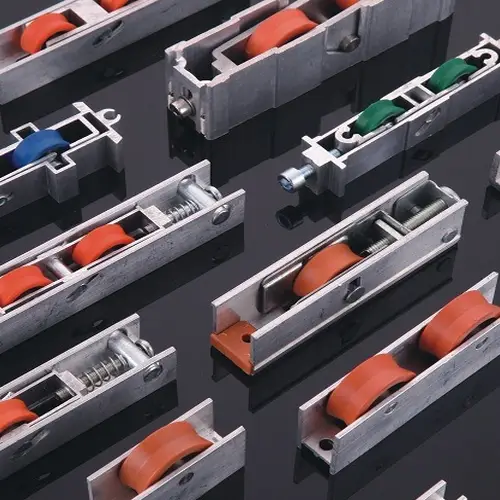

China Manufacturer: High Precision Polyurethane PU Roller Nylon Wheel Rubber Sheet Urethane Pulley for Silicon Wafer Cutting Machinery Air Compressor for Car

Product Description

Polyurethane rollers, pulleys, and wheels are widely used in the photovoltaic and semiconductor industries due to their high wear and abrasion resistance. The castable polymer class of polyurethane offers exceptional properties such as excellent wear resistance, ease of use and molding, resistance to harsh environments (heat, acids, oil), high noise reduction, and high-quality surface finish. These characteristics make polyurethane an ideal material for creating custom-designed wheels and rotating components.

Product Parameters

Benefits of Polyurethane Wheels:

- A very long service life compared to plastic, rubber, and steel wheels

- Incredible noise reduction

- Better grip and high traction for paper, glass, wood, etc.

- FDA approval for food processing and clean rooms

- Strong resistance to abrasion, harsh chemicals, acids, and solvents

- Decreased conveyor system downtime

- Customizable non-marking colors

- Customizable hardnesses, ranging from sponge-soft to iron-strong

- The ability to handle extreme temperatures, both hot and cold

- Increased profitability

Detailed Photos

[Insert detailed photos here]

About Our Company

Our company is a leading supplier of various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, competitive prices, and excellent customer service. We welcome customers to customize drawings and samples to meet their specific requirements.

Frequently Asked Questions (FAQs)

- How long is the service life of polyurethane wheels compared to other materials?

- Are polyurethane wheels suitable for use in food processing environments?

- Do polyurethane wheels offer better grip and traction?

- Can polyurethane wheels withstand extreme temperatures?

- What are the advantages of using polyurethane wheels in the photovoltaic and semiconductor industries?

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to purchase. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Roller Pulley

Roller pulleys are known for their exceptional performance characteristics. Let’s delve into each point in detail:

Point 1: High Durability

One of the key performance characteristics of roller pulleys is their exceptional durability. These pulleys are designed to withstand heavy loads and constant use, ensuring longevity for various applications.

Point 2: Smooth Operation

Roller pulleys offer smooth operation, minimizing friction and allowing for efficient conveyance of materials. This smoothness ensures minimal wear and tear on the system, leading to improved productivity and reduced maintenance requirements.

Point 3: Versatility

Another notable characteristic of roller pulleys is their versatility. These pulleys can be used in a wide range of industries and applications, making them a reliable choice for various conveyor systems, automotive machinery, industrial machinery, agricultural equipment, and exercise equipment.

Types and Characteristics of Roller Pulley

There are different types of roller pulleys available, each with its unique characteristics. Let’s explore some of the common types:

Type 1: Steel Roller Pulley

Steel roller pulleys are known for their strength and durability. These pulleys can handle heavy loads and are suitable for demanding industrial applications.

Type 2: Plastic Roller Pulley

Plastic roller pulleys offer excellent corrosion resistance and are lightweight. They are commonly used in conveyor systems where non-metallic materials are preferred.

Type 3: Rubber Coated Roller Pulley

Rubber coated roller pulleys provide superior traction and grip, making them ideal for applications where slip resistance is crucial, such as exercise equipment.

Advantages of Different Materials for Roller Pulley

The choice of material for roller pulleys can significantly impact their performance. Here are the advantages of roller pulleys made from different materials:

Advantage 1: Steel Roller Pulley

Steel roller pulleys offer exceptional strength and durability, making them suitable for heavy-duty applications. They can withstand high loads and harsh operating conditions.

Advantage 2: Plastic Roller Pulley

Plastic roller pulleys are lightweight and corrosion-resistant. They are an ideal choice for applications where weight reduction and resistance to chemicals are essential.

Advantage 3: Rubber Coated Roller Pulley

Rubber coated roller pulleys provide enhanced grip and traction. They are particularly beneficial in applications where slip resistance is critical, ensuring safe and efficient operation.

Application of Roller Pulley

The versatility of roller pulleys makes them indispensable in various industries. Let’s explore their applications in different fields:

Conveyor Systems

Roller pulleys play a vital role in conveyor systems, ensuring smooth and efficient material handling. They facilitate the movement of goods in industries such as manufacturing, logistics, and distribution.

Automotive Industry

In the automotive industry, roller pulleys are used in assembly lines and production processes. They enable the smooth transportation of components, enhancing overall productivity.

Industrial Machinery

Industrial machinery relies on roller pulleys for tasks such as power transmission and conveying materials within the production environment. These pulleys contribute to the seamless operation of various machines.

Agricultural Equipment

Roller pulleys find applications in agricultural equipment, where they assist in tasks such as harvesting, grain handling, and conveyor systems in farms and agricultural processing facilities.

Exercise Equipment

Roller pulleys are an essential component in exercise equipment, ensuring smooth and controlled movement during workouts. They contribute to a safe and effective exercise experience.

Future Development Trends and Opportunities

The future of roller pulley products is promising, with several development trends and opportunities on the horizon. Here are some noteworthy points:

Development Trend 1: Advancements in Material Technology

Ongoing advancements in material technology will lead to the development of new materials with enhanced properties. This will further expand the range of roller pulley options available, catering to specific industry needs.

Development Trend 2: Automation and Industry 4.0

The rise of automation and Industry 4.0 will drive the demand for efficient conveyor systems and machinery. Roller pulleys, as a crucial component, will witness increased adoption in automated production environments.

Development Prospect: Increased Efficiency and Cost Savings

The continuous improvement of roller pulley design and materials will result in increased efficiency and cost savings for industries. This will lead to improved productivity, reduced maintenance, and enhanced overall operational performance.

How to Choose a Suitable Roller Pulley

Choosing the right roller pulley is essential for optimal performance. Consider the following aspects when selecting a suitable roller pulley:

Aspect 1: Load Capacity

Determine the load capacity requirements based on the specific application. Ensure that the chosen roller pulley can withstand the anticipated load without compromising performance.

Aspect 2: Material

Select the material of the roller pulley based on the environmental conditions and the desired characteristics, such as strength, corrosion resistance, or grip.

Aspect 3: Diameter and Size

Consider the diameter and size of the roller pulley to ensure compatibility with the existing system and the desired conveying speed.

Aspect 4: Type of Pulley and Bore Size

Choose the appropriate type of roller pulley based on the specific requirements of the application. Additionally, consider the bore size to ensure proper installation and compatibility with the shaft.

Summary

Roller pulleys are essential components in various industries, offering exceptional durability, smooth operation, and versatility. The choice of materials, such as steel, plastic, or rubber-coated, provides unique advantages for different applications. Their widespread use in conveyor systems, automotive industry, industrial machinery, agricultural equipment, and exercise equipment showcases their value and importance. As the future unfolds, roller pulleys will continue to evolve, presenting new opportunities and contributing to increased efficiency and cost savings. When selecting a roller pulley, consider factors such as load capacity, material, diameter and size, type of pulley, and bore size. By making an informed choice, you can ensure optimal performance and reliability for your specific application.

Author: Dream