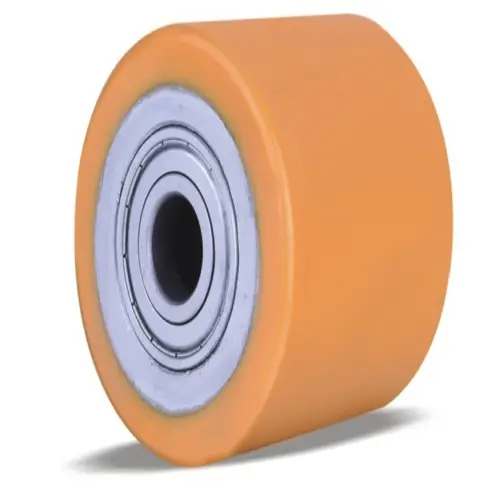

Top Quality 0005501933 4572001070 Heavy Duty Timing Belt Tension Pulley Roller for European Trucks

This heavy-duty timing belt tension pulley roller is perfect for European trucks, specifically the MBZ OM457 and OM502 models. Made with durable materials, it ensures long-term use and high performance. Its nice-looking packaging makes it easy to store and transport, while its prompt delivery ensures timely use. With a wide range of parts for more models available, it is the most competitive wholesale prices in China. One-stop buying service is also provided for complete convenience.

Advantages of Our Timing Belt Tension Pulley Roller

- Durable and high quality

- Nice-looking packaging

- Prompt delivery

- Wide range of parts for more models available

- Most competitive wholesale prices

- One-stop buying service provided

Our company has been providing genuine and high-quality engine parts at the lowest possible cost in China, earning a high reputation from clients due to reliable quality, competitive pricing, and on-time delivery. We guarantee the best quality, and we only partner with reputable OEM factories in China to ensure quality assurance. Our competitive pricing for OEM, high-quality, and after-sale parts is second to none, and our one-stop service means you can contact us at any time if you have any questions or concerns. We provide the cheapest shipping cost available through our long-standing partnership with the best freight forwarders. And customers are welcome to customize drawings and samples for their specific needs, with one sale completing the whole case for the customer.

Other Industrial Products We Offer

In addition to our heavy-duty timing belt tension pulley roller, our company also supplies various products for industrial use, including but not limited to:

- Agricultural gearboxes

- Power output shafts

- Sprockets

- Fluid couplings

- Worm gear reducers

- Gears and racks

- Roller chains

- Pulleys

- Planetary gearboxes

- Timing pulleys

- Bushings

Our company emphasizes high-quality products, competitive pricing, and considerate service. We encourage customers to browse our extensive selection and experience the same quality and satisfaction that our existing clients enjoy.

Frequently Asked Questions

Q1: What are your packaging conditions?

We pack our goods in neutral white boxes and brown cartons. We can package the goods in your branded box if you have a legally registered patent and provide us with an authorization letter.

Q2: What are your payment terms?

We require a 30% deposit and 70% balance payment before delivery. We will show you photos of the products and packaging before you pay the balance.

Q3: What are your delivery terms?

We offer FOB price.

Q4: What is your delivery time?

Generally speaking, it takes 15 to 30 days after receiving the advance payment. The exact delivery time depends on the item and quantity of your order.

Q5: How do you maintain a long-term good relationship with your customers?

We maintain good quality and competitive prices to ensure our customers benefit. We are sincere in doing business and making friends.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to purchase. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Roller Pulley

Roller pulleys are known for their exceptional performance characteristics. Let’s delve into each point in detail:

Point 1: High Durability

One of the key performance characteristics of roller pulleys is their exceptional durability. These pulleys are designed to withstand heavy loads and constant use, ensuring longevity for various applications.

Point 2: Smooth Operation

Roller pulleys offer smooth operation, minimizing friction and allowing for efficient conveyance of materials. This smoothness ensures minimal wear and tear on the system, leading to improved productivity and reduced maintenance requirements.

Point 3: Versatility

Another notable characteristic of roller pulleys is their versatility. These pulleys can be used in a wide range of industries and applications, making them a reliable choice for various conveyor systems, automotive machinery, industrial machinery, agricultural equipment, and exercise equipment.

Types and Characteristics of Roller Pulley

There are different types of roller pulleys available, each with its unique characteristics. Let’s explore some of the common types:

Type 1: Steel Roller Pulley

Steel roller pulleys are known for their strength and durability. These pulleys can handle heavy loads and are suitable for demanding industrial applications.

Type 2: Plastic Roller Pulley

Plastic roller pulleys offer excellent corrosion resistance and are lightweight. They are commonly used in conveyor systems where non-metallic materials are preferred.

Type 3: Rubber Coated Roller Pulley

Rubber coated roller pulleys provide superior traction and grip, making them ideal for applications where slip resistance is crucial, such as exercise equipment.

Advantages of Different Materials for Roller Pulley

The choice of material for roller pulleys can significantly impact their performance. Here are the advantages of roller pulleys made from different materials:

Advantage 1: Steel Roller Pulley

Steel roller pulleys offer exceptional strength and durability, making them suitable for heavy-duty applications. They can withstand high loads and harsh operating conditions.

Advantage 2: Plastic Roller Pulley

Plastic roller pulleys are lightweight and corrosion-resistant. They are an ideal choice for applications where weight reduction and resistance to chemicals are essential.

Advantage 3: Rubber Coated Roller Pulley

Rubber coated roller pulleys provide enhanced grip and traction. They are particularly beneficial in applications where slip resistance is critical, ensuring safe and efficient operation.

Application of Roller Pulley

The versatility of roller pulleys makes them indispensable in various industries. Let’s explore their applications in different fields:

Conveyor Systems

Roller pulleys play a vital role in conveyor systems, ensuring smooth and efficient material handling. They facilitate the movement of goods in industries such as manufacturing, logistics, and distribution.

Automotive Industry

In the automotive industry, roller pulleys are used in assembly lines and production processes. They enable the smooth transportation of components, enhancing overall productivity.

Industrial Machinery

Industrial machinery relies on roller pulleys for tasks such as power transmission and conveying materials within the production environment. These pulleys contribute to the seamless operation of various machines.

Agricultural Equipment

Roller pulleys find applications in agricultural equipment, where they assist in tasks such as harvesting, grain handling, and conveyor systems in farms and agricultural processing facilities.

Exercise Equipment

Roller pulleys are an essential component in exercise equipment, ensuring smooth and controlled movement during workouts. They contribute to a safe and effective exercise experience.

Future Development Trends and Opportunities

The future of roller pulley products is promising, with several development trends and opportunities on the horizon. Here are some noteworthy points:

Development Trend 1: Advancements in Material Technology

Ongoing advancements in material technology will lead to the development of new materials with enhanced properties. This will further expand the range of roller pulley options available, catering to specific industry needs.

Development Trend 2: Automation and Industry 4.0

The rise of automation and Industry 4.0 will drive the demand for efficient conveyor systems and machinery. Roller pulleys, as a crucial component, will witness increased adoption in automated production environments.

Development Prospect: Increased Efficiency and Cost Savings

The continuous improvement of roller pulley design and materials will result in increased efficiency and cost savings for industries. This will lead to improved productivity, reduced maintenance, and enhanced overall operational performance.

How to Choose a Suitable Roller Pulley

Choosing the right roller pulley is essential for optimal performance. Consider the following aspects when selecting a suitable roller pulley:

Aspect 1: Load Capacity

Determine the load capacity requirements based on the specific application. Ensure that the chosen roller pulley can withstand the anticipated load without compromising performance.

Aspect 2: Material

Select the material of the roller pulley based on the environmental conditions and the desired characteristics, such as strength, corrosion resistance, or grip.

Aspect 3: Diameter and Size

Consider the diameter and size of the roller pulley to ensure compatibility with the existing system and the desired conveying speed.

Aspect 4: Type of Pulley and Bore Size

Choose the appropriate type of roller pulley based on the specific requirements of the application. Additionally, consider the bore size to ensure proper installation and compatibility with the shaft.

Summary

Roller pulleys are essential components in various industries, offering exceptional durability, smooth operation, and versatility. The choice of materials, such as steel, plastic, or rubber-coated, provides unique advantages for different applications. Their widespread use in conveyor systems, automotive industry, industrial machinery, agricultural equipment, and exercise equipment showcases their value and importance. As the future unfolds, roller pulleys will continue to evolve, presenting new opportunities and contributing to increased efficiency and cost savings. When selecting a roller pulley, consider factors such as load capacity, material, diameter and size, type of pulley, and bore size. By making an informed choice, you can ensure optimal performance and reliability for your specific application.

Author: Dream